TCC-2000 Torque Controller

TCC-2000 Torque Controller: Advanced Torque Management for Pneumatic Tools with Bluetooth Connectivity for Windows PC/Laptop or Android devices

The TCC-2000 Torque Controller is a cutting-edge solution for precise torque control of pneumatic tools, including impact wrenches, oil pulse tools, nut runners, and clutch tools. This controller features seamless Bluetooth (BT) connectivity, enabling easy setup and configuration via a Windows-based PC/Laptop or Android device. The TCC-2000 is engineered to optimize torque application, ensuring consistent and accurate results across various industrial applications.

Key Features and Benefits

- Precision Torque Control: The TCC-2000 provides accurate control over the torque output of various pneumatic tools, ensuring that each fastener is tightened to the exact required specifications. This precision is critical for maintaining the quality and safety of assemblies in demanding industrial environments.

- Wide Tool Compatibility: Designed to work with a broad spectrum of pneumatic tools, including impact wrenches, oil pulse tools, nut runners, and clutch tools, the TCC-2000 offers versatility across multiple applications, making it a valuable tool for industries such as automotive, aerospace, and general manufacturing.

- Bluetooth Connectivity for Windows: The TCC-2000 uses Bluetooth technology to connect wirelessly to Windows-based PCs and laptops. This connectivity simplifies setting up and configuring the controller, making it easy to adjust torque settings, monitor performance, and manage data directly from your computer.

- User-Friendly Software Interface: The TCC-2000 is operated through an intuitive software interface compatible with Windows systems. This interface offers a straightforward way to configure torque settings, create and store multiple profiles, and monitor real-time data. The software is designed to be user-friendly, reducing the time needed for setup and minimizing the learning curve for new users.

- Real-Time Monitoring and Data Logging: The TCC-2000 can monitor the torque application in real time via the connected PC or laptop, ensuring that operations are performed within the specified parameters. It also offers data logging capabilities, enabling users to record and analyze torque data for quality control, process optimization, and compliance documentation.

- Customizable Torque Profiles: The TCC-2000 allows creating and storing multiple profiles tailored to different tools or tasks. This feature is especially useful in production environments where various torque requirements must be met efficiently, allowing quick transitions between different job setups.

- Durable and Reliable Construction: Built to withstand demanding industrial conditions, the TCC-2000 features a rugged design that ensures durability and reliable performance. It is resistant to vibration, dust, and other environmental factors commonly encountered in manufacturing and assembly lines.

- Safety Features: The TCC-2000 includes advanced safety features such as overload protection and automatic shutoff when abnormal torque levels are detected. These features help protect the equipment and operators, reducing the likelihood of damage or injury.

- Easy Integration and Setup: The TCC-2000 can be easily integrated into existing systems thanks to its Bluetooth connectivity and Windows-based software. Its compact design and versatile mounting options make it adaptable to various industrial settings.

Applications

The TCC-2000 Torque Controller is ideal for a wide range of industrial applications, including:

- Automotive Manufacturing: Provides precise torque control for the assembly of critical components, ensuring the safety and reliability of vehicles.

- Aerospace Assembly: Delivers accurate torque management for aircraft assembly, where precision is crucial for flight safety and performance.

- Industrial Equipment Maintenance: Ensures that machinery components are tightened to the correct specifications, enhancing the longevity and performance of industrial equipment.

- Production and Assembly Lines: Supports high-precision torque control for consistent product quality and process efficiency in manufacturing environments.

Why Choose the TCC-2000 Torque Controller?

The TCC-2000 Torque Controller offers a powerful combination of precision, versatility, and ease of use, making it an essential tool for professionals who demand reliable torque management. Its Bluetooth connectivity to Windows-based PCs and laptops enhances setup and configuration processes, while its robust construction ensures long-term durability in challenging industrial environments. Whether you’re working in automotive, aerospace, manufacturing, or equipment maintenance, the TCC-2000 provides the control and flexibility needed to achieve superior results.

- With a patented control algorithm and device for controlling the output torque of all continuous and discontinuous air-driven torque tools, especially air impact wrenches, air ratchet wrenches, air oil pulse wrenches, as well as geared torque multipliers, regardless of tool brand and its designed mechanism with proven satisfactory control accuracy and durability.

- Programmable function of bolting sequence control while applying with the tagged bolt or sensing bolt.

- It solves problems of torque loss that may be caused by the variation of the joint hardness, the rise in hydraulic fluid temperature in pulse tools, or the posture of holding the tool during continuous operation. It compensates the dynamic torque loss automatically within its allowable working torque range.

Standard Packaging:

Controller, Power cable, Air Hose Coupler, Antenna x 2., TCA-IPC01 Controller Inlet – 2M hose+coupler + F.R unit -10kg/cm2 max., & TCA-OPC01 Controller Outlet – 3M hose+coupler.

Optional Accessories:

- 24V Tri-color light pole w/ Buzzer

- Barcode Scanner

- Printer.

| Optional: ZTPAMB6-73ROG 24V Tri-color light pole w/ Buzzer |

Minimum system requirements:

- Windows:

Operating system: Windows 10 or above

Minimum CPU: Core i3

Minimum system memory (RAM): 4G

Minimum free storage space: 32GB - Android:

Operating system: Android 7.0 or above

Minimum CPU: Quad-core

Minimum system memory (RAM): 3G

Minimum free storage space: 16GB

Software & Functions

- Pulse Wrench

– Transducer mode (Work with transducer)

– Pressure mode (Without transducer)

– Track mode (For soft joint) - Torque wrench

– Torque

– Torque + Angle

– Click wrench track mode

– Click wrench inspection mode - Impact Wrench

– Transducer mode (Work with transducer)

– Pressure mode (Work without transducer)

– Track mode (For soft joint) - Job sequence

Geared Wrench ( Opt. mode)

Torque Tester ( Opt. mode)

Torque multiplier ( Opt. mode) - Signal Source: Torque Transducer, Air Pressure Sensor, Sensing Bolt or Tagged Bolt.

- Torque Revise: Deviation & Replacement.

- Tool Torque Capacity Calibration: Easy set-up TH & TL within operable working air pressure range in minutes.

- Target Torque Setting: Any target torque value can be selected and inputted within the calibrated torque range.

- Working air pressure: Automatic adjusted to correspondent target torque(Inlet Air Pressure between 100~120psi is recommended).

- Air flow rate: Only TCA/TCC has a digital flow meter. Turn the tool’s airflow regulator to the maximum, and the system will automatically regulate the proper flow rate to the corresponding target torque.

- Bolting in stages: As required, set the bolting stages and the percentage of target torque for each stage from 1 to 4. The system will regulate the air pressure and flow rate accordingly.

- Number of bolts: Preset the number of bolts to be fastened. When all bolts of each stage are fastened, the system switches to the next stage and regulates the air pressure and flow rate accordingly and automatically.

- Torque Compensation: The system will compensate the torque loss that may be caused by the variation in the bolted joint hardness, the rise in temperature of the pulse wrench’s hydraulic fluid, or the operator’s posture to hold the tool during the process automatically within its allowable working air pressure range.

- Remote monitoring: You can monitor data on your cell phone, tablet, and PC or set parameters on the torque controller via the Internet or Ethernet with VNC.

- Operation Management: Constraints: Access the operable functions, such as logging the operator’s ID and duration of operation, via permission setting.

- Torque Control Accuracy: ±5%~±15%.

- Job Sequence: Support 10 torque tool presets available for bolting sequentially.

- Production Record: It can be traced through USB or Ethernet or exported to the cloud server through wired or wireless connections.

- Torque Controller Warranty period:

* 12 months from purchase date.

* Manufacturer will repair or replace defects due to faulty materials or workmanship. This Warranty does not cover part failure due to broken/missing seal labels, misuse, modification, negligence, abuse, or normal wear and tear.

| Model | TCA-2000 | TCB-2000 | TCC-2000 | |

| Max. Flow Rate | 2000 L/min | 2000 L/min | 2000 L/min | |

| Touch Panel Size | 10″ Touch Panel | PC / Laptop / Tablet | PC / Laptop / Tablet | |

| Power Source | AC 100V~240V /2A | AC 100V~240V /2A | AC 100V~240V /2A | |

| Connection Port | USB | 1 | 1 | 1 |

| RS232 | 2 | 1 | N/A | |

| RJ45 | 1 | N/A | N/A | |

| Wireless Antenna | RF2.4G | 2 | 1 | 1 |

| BT2.4G | N/A | 1 | 1 | |

| Antenna | 2 | 2 | 2 | |

| Light Tower Output Port | 1 | 1 | 1 | |

| Buzzer | 80dB | 80dB | 80dB | |

| USB Charger Port | 2 | 1 | 1 | |

| Flow Rate Detection | Yes | No | No | |

| Automatic Flow rate Control | Yes | No | No | |

| Operation Mode | Pressure Mode | Yes | Yes | Yes |

| Transducer Mode | Yes | Yes | Yes | |

| Accu Mode | Yes | Yes | N/A | |

| Job Sequence | Yes | Yes | N/A | |

| Control Accuracy | Air Impact Wrench | ±10%~±20% | ±10%~±20% | ±10%~±20% |

| Air Pulse Wrench | ±5%~±15% | ±5%~±15% | ±5%~±15% | |

| Air Torque Multiplier | ±5% | ±5% | ±5% | |

| Thread Size | Inlet | 1/2″ NPT | 1/2″ NPT | 1/2″ NPT |

| Outlet | 1/2″ NPT | 1/2″ NPT | 1/2″ NPT | |

| Language | Simplified/Traditional Chinese, English, Japanese, Spanish | Simplified/Traditional Chinese, English, Japanese, Spanish, Italian, Indonesian | Simplified/Traditional Chinese, English, Japanese, Spanish, Italian, Indonesian | |

| System Parameter | Yes | Yes | Yes | |

| Tyre Assembly System -Job Sequence | No | Yes | No | |

| Display | HMI onboard | External display | External display | |

| Job Data | Full Job report | Full Job report | Full Job report | |

| Cloud | FTP | WEB | WEB | |

| Job Data Export | All data in CSV/EXCEL format | Available in CSV/Excel, PDF format | Available in CSV/Excel, PDF format | |

| Job Data Memory | 150K | No Limit (Depends on available disk space) | No Limit (Depends on available disk space) | |

| Torque Curve Display | No | Yes | Yes | |

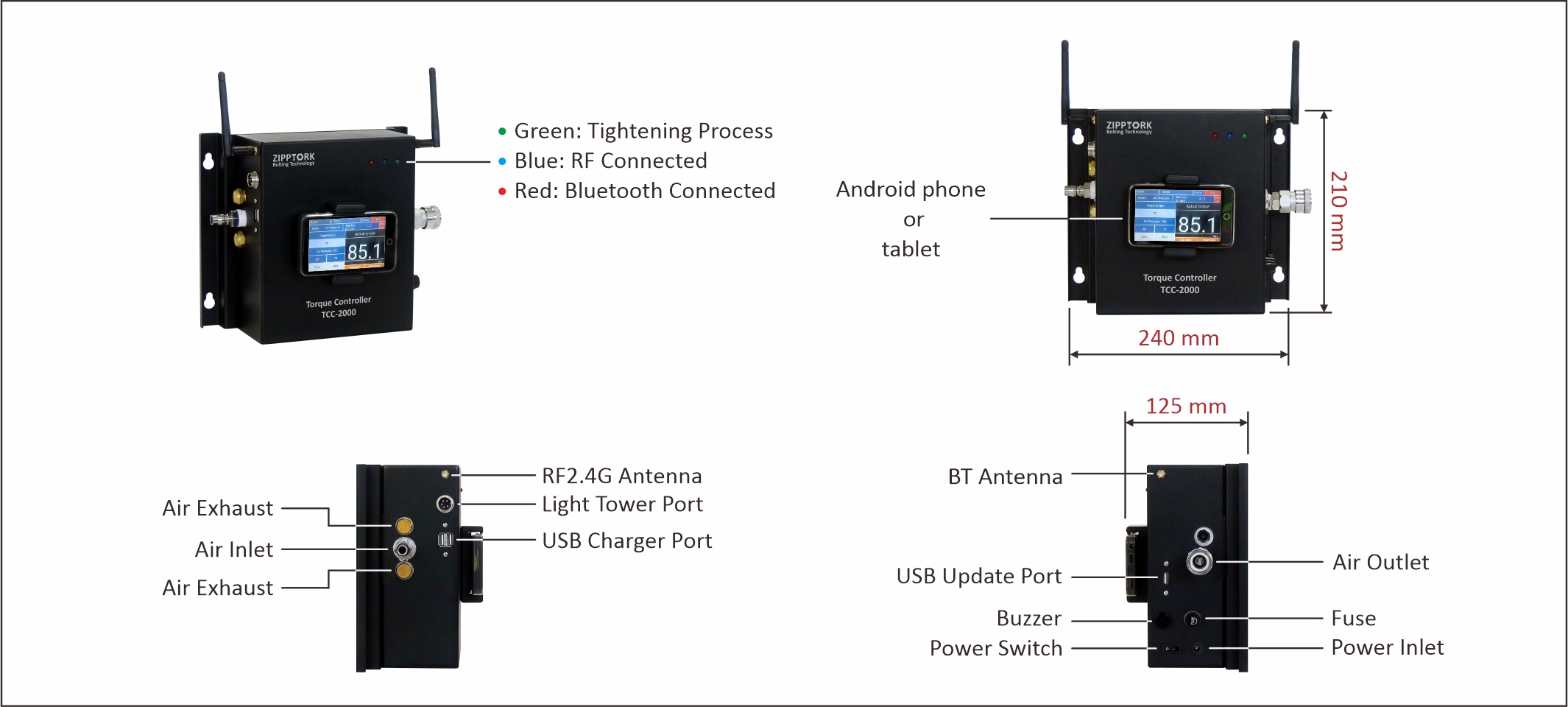

| Dimensions | Length(L) | 370mm | 320mm | 210mm |

| Width(W) | 214mm | 217mm | 240mm | |

| High(H) | 266mm | 210mm | 125mm | |

| Net Weight | 10.5kg±0.5kg | 6kg±0.5kg | 3.7kg±0.2kg | |

| Operating System | Linux | Windows | Android/Windows | |

The TCB-2000 Torque Controller is an advanced device designed to provide precise torque management for various pneumatic tools, including impact wrenches, pulse tools, nut runners, and clutch tools. Equipped with an intuitive Human-Machine Interface (HMI) touch panel, the TCB-2000 offers user-friendly control and monitoring, making it an essential tool for applications requiring consistent and accurate torque delivery.

The TCB-2000 Torque Controller is an advanced device designed to provide precise torque management for various pneumatic tools, including impact wrenches, pulse tools, nut runners, and clutch tools. Equipped with an intuitive Human-Machine Interface (HMI) touch panel, the TCB-2000 offers user-friendly control and monitoring, making it an essential tool for applications requiring consistent and accurate torque delivery.