ZB71CCQ Air Screwdriver / Pistol Type

The ZB71CCQ Air Screwdriver is a high-performance pneumatic tool designed for precision fastening tasks in industrial and assembly environments. Known for its lightweight construction and fast operation, this air screwdriver is ideal for applications that demand efficiency, reliability, and accuracy. Its compact design and advanced torque control make it perfect for electronics, automotive, furniture manufacturing, and other industries where repetitive screwing tasks are expected.

Key Features and Benefits

1. High Speed and Performance:

- The ZB71CCQ enhances productivity on production lines and assembly tasks and is designed to provide consistent torque with rapid fastening speeds.

- Powered by a pneumatic system, ensuring long working hours without overheating compared to electric alternatives.

2. Precision Torque Control:

- Supports adjustable torque settings, ensuring screws are fastened to the correct tension, preventing over-tightening or under-tightening.

- It is ideal for assembling products where precision is critical, such as electronics, machinery, and automotive parts.

3. Lightweight and Ergonomic Design:

- Constructed with a lightweight composite body, the ZB71CCQ minimizes user fatigue during continuous operation.

- Features an ergonomically shaped handle for improved comfort and reduced strain during extended use.

4. Quick-Change Bit Mechanism:

- The quick-release chuck allows for fast switching between different screw bits, increasing efficiency.

- Compatible with a wide range of bits for diverse applications, including Phillips, slotted, hex, and Torx bits.

5. Noise-Reduced Operation:

- Engineered to deliver low-noise performance, making it suitable for use in noise-sensitive environments.

- Reduces fatigue associated with long working hours in assembly lines.

6. Durable Construction:

- Built with high-quality materials, the ZB71CCQ is designed to withstand continuous industrial use with minimal maintenance.

- A corrosion-resistant body protects the tool from wear and tear, extending its service life.

Applications

The ZB71CCQ Air Screwdriver is ideal for a wide range of industries and applications:

- Electronics Assembly: Securing small screws in delicate devices without damaging components.

- Automotive Production: Fastening interior and exterior components where consistent torque is critical.

- Furniture Manufacturing: Assists in rapid assembly of flat-pack furniture and cabinetry.

- Appliance Assembly: Used in fastening tasks for household and industrial appliances.

- Aerospace Industry: Precision fastening of lightweight components requiring strict torque specifications.

Why Choose the ZB71CCQ Air Screwdriver?

The ZB71CCQ Air Screwdriver offers an unbeatable combination of speed, accuracy, and ease of use, making it a go-to tool for assembly lines and repair applications. Its ergonomic design, quick-change capability, and torque precision ensure high-quality results while minimizing operator fatigue. Whether you are working on large-scale production or precise assembly tasks, the ZB71CCQ will deliver reliable performance every time.

.

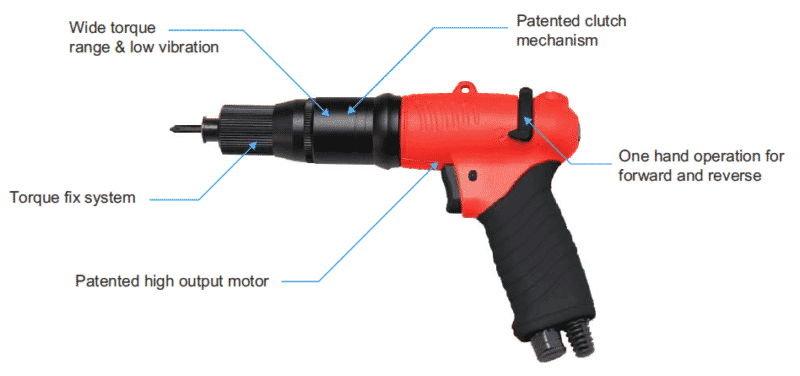

- Torque fix system

- Wide torque range & low vibration

- Patented clutch mechanism

- Patented high-output motor

- One-hand operation for forward and reverse

Motor Comparison

![]() Patented motor

Patented motor

![]() Traditional motor

Traditional motor

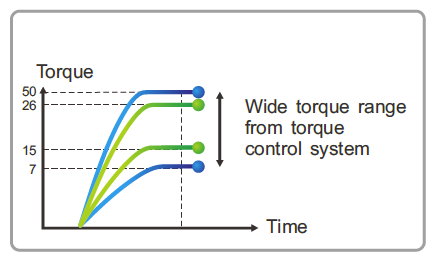

Torque schematic diagram

![]() Patented torque control system

Patented torque control system

![]() Traditional torque control system

Traditional torque control system

Specification:

- Free Speed: 550 rpm.

- Net Weight: 980 g

- O.A.L: 220 mm

- Dia.: 43 mm

- High: 220 mm

- Air Pressure: 6 Kg/cm3

- Min. air hose bore: 8 mm

- Air Consumption: 0.55 m3/min

- Torque range: 30-110 Kgf-cm

- Standard Deviation: ±3 %

- Fastening Capacity/Machine Screw Dia.: M5.0-M7.3

- Fastening Capacity/Tapping Screw Dia.: M4.0-M6.2

| Model | Free Speed rpm | Weight g | O.A.L mm | Dia. mm | High mm | Air Pressure kg/cm³ | Min. air hose bore mm | Air Consumption m³/min | Torque range kgf-cm | Standard Deviation % | Fastening Capacity | |

| Machine Screw Dia. | Tapping Screw Dia | |||||||||||

| ZB46CCQ | 2200 | 640 | 190 | 35 | 190 | 6.0 | 5.0 | 0.28 | 3-20 | ±3 | M2.2-M4.5 | M1.7-M3.5 |

| ZB49CCQ | 1800 | 640 | 190 | 35 | 190 | 6.0 | 5.0 | 0.28 | 3-25 | ±3 | M2.2-M4.7 | M1.7-M3.8 |

| ZB52CCQ | 1000 | 640 | 190 | 35 | 190 | 6.0 | 5.0 | 0.28 | 5-35 | ±3 | M2.8-M5.2 | M2.2-M4.2 |

| ZB58CCQ | 550 | 640 | 190 | 35 | 190 | 6.0 | 5.0 | 0.28 | 10-50 | ±3 | M3.6-M6.0 | M2.8-M4.7 |

| ZB59CCQ | 1700 | 980 | 220 | 43 | 220 | 6.0 | 8.0 | 0.55 | 7-50 | ±3 | M2.9-M6.0 | M2.6-M4.9 |

| ZB61CCQ | 1400 | 980 | 220 | 43 | 220 | 6.0 | 8.0 | 0.55 | 10-60 | ±3 | M3.6-M6.2 | M2.8-M5.1 |

| ZB66CCQ | 1000 | 980 | 220 | 43 | 220 | 6.0 | 8.0 | 0.55 | 12-75 | ±3 | M3.8-M6.6 | M3.0-M5.6 |

| ZB71CCQ | 550 | 980 | 220 | 43 | 220 | 6.0 | 8.0 | 0.55 | 30-110 | ±3 | M5.0-M7.3 | M4.0-M6.2 |

| ZB76CCQ | 300 | 1100 | 220 | 43 | 220 | 6.0 | 8.0 | 0.55 | 30-180 | ±3 | M5.0-M9.3 | M4.0-M7.2 |

| ZB79CCQ | 250 | 1250 | 220 | 43 | 220 | 6.0 | 8.0 | 0.55 | 50-280 | ±3 | M6.0-M11.0 | M4.9-M8.7 |